WHICH ALUMINUM ALLOY BENDS BEST?

“Which aluminum alloy bends the best?” is a a common question customers want the answer to. In this post, we’ll explain it to you.

“Which aluminum alloy bends the best?” is a a common question customers want the answer to. In this post, we’ll explain it to you.To understand this better, we need to talk about alloys, which is the first factor to consider upon selection. In aluminum, we have various designations that all have different chemical compositions, making them applicable in various fields of metal processing. The most important ones are:

So, we see that specific alloys have a high degree of formability that provide the proper behaviour in processing and especially in bending.

FACTOR 2 – THICKNESS AND BEND RADIUS

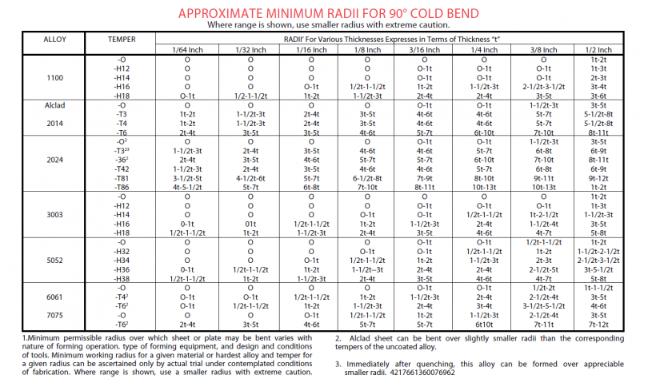

Another factor to consider is that during the process of bending, the metal hardens and strengthens by reason of the working effect. Apart from alloy selection, thickness and bend radius are also critical factors that must be considered. The table below shows the permitted bend radii for 90o bending.

FACTOR 3 – PERCENTAGE OF ELONGATION

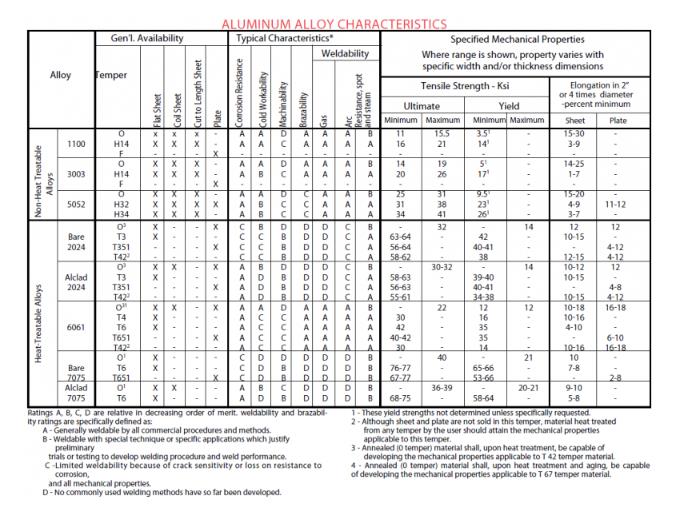

A third factor to be considered is that formability of a specific alloy can be found in the percentage of elongation and the difference between yield strength and ultimate tensile strength.

This rule states that the higher the elongation value (the wider the range between yield and tensile strength), the better the forming ability of the alloy.

From the aforementioned descriptions of alloys and the data shown in table 3 (below), it is quite obvious that the best series for forming, and thus for bending, are series 3xxx, 5xxx, and in some cases 6xxx. Series 2xxx and 7xxx are not to be considered and thus should be avoided due to being extremely strong. They are difficult to form in any way.

Top 3 Aluminum Alloys For Bending

1. 3003. This would be the best solution for most application. This alloy exhibits medium strength, the best cold workability together with high elongation such as 25% and one of the biggest differences between yield and tensile strength of 14 Ksi (Kilo-pound of force per square inch) at 0 temper – annealed, by the H14 temper which is partially annealed and strain hardened.

2. 5052. 5052 is a close second. At the annealed temper, it has an elongation of 20% and the difference between yield and tensile strength of 21.5 Ksi. It is the highest strength alloy of the more common non-heat treatable grades. It has excellent corrosion behavior and in the annealed condition has better formability than 3003 or even 1100 alloys, with 21.5 Ksi of difference between yield and tensile strength and up to 20% of elongation.

3. 6061. This is one of the most versatile of the heat treatable family of alloys. In the annealed condition, it can be used for bending since the difference between yield and tensile strength is 10 Ksi and elongation is up to 18%. When moving up to T4 and T6 tempers, however, bending ability tends to decrease. Bending these temered alloys is not impossible, but requires great caution and probably larger bending radii to avoid cracking.

7005 and 2024 alloys are not recommended for bending, since they are both alloys with great strength and forming capabilities which are very limited even in annealed condition.

Aside from these, special products such as ATP-5, K100-S, Duramold-2, Duramold-CS and M-1 are not recommended for bending applications. Table_3 below shows characteristics of the alloys discussed previously.

ADDITIONAL QUESTIONS

If you’d like to know more about bending specific alloys or which alloy is best for your application, please reach out Far East Tech co. Ltd.

Far East Tech has more than 15 years of rich experience in the precision machining industry and has an excellent reputation. The company is equipped with a professional technical team and precision processing machines, which can provide you with one-stop service.

© 著作権: 2026 Far East Tech CO., Ltd. 全著作権所有.

サポートされているIPv6ネットワーク